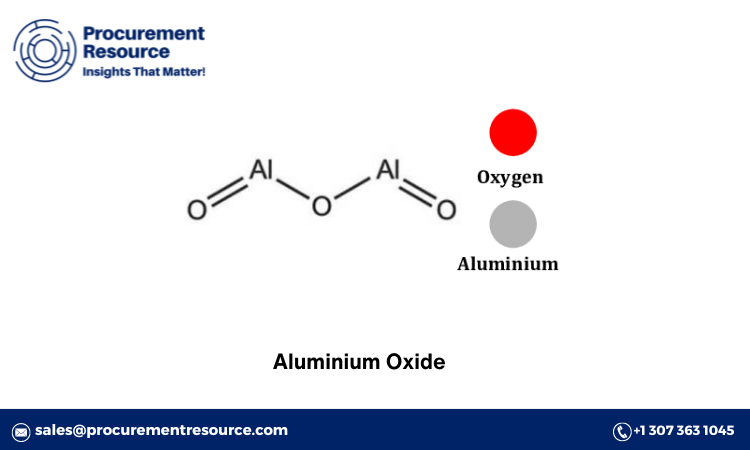

Aluminium oxide (Al2O3), commonly known as alumina, is a crucial material used in various industrial applications, including the manufacturing of aluminum, ceramics, refractories, and abrasives. It plays a vital role in the production of aluminum metal through the Hall-Héroult process. The price trend of aluminium oxide is influenced by several factors such as supply-demand dynamics, raw material costs, energy prices, and geopolitical events. Understanding the price trend of aluminium oxide is essential for industries that rely on this material to make informed purchasing and investment decisions.

Forecast Report

The forecast for aluminium oxide prices involves an in-depth analysis of the current market conditions, historical data, and future projections. The price of aluminium oxide is expected to remain volatile due to fluctuations in the supply chain, energy costs, and global economic conditions. However, certain trends can provide a general direction for future prices.

Request For Sample: https://www.procurementresource.com/resource-center/aluminium-oxide-price-trends/pricerequest

-

Supply Chain Dynamics: The supply of bauxite, the primary raw material for aluminium oxide, is critical in determining its price. Any disruptions in bauxite mining, whether due to environmental regulations, political instability in bauxite-rich regions, or natural disasters, can lead to a spike in aluminium oxide prices.

-

Energy Costs: The production of aluminium oxide is energy-intensive. Changes in energy prices, particularly electricity and natural gas, can significantly impact production costs and, consequently, the price of aluminium oxide. As the world transitions to greener energy sources, the cost implications for energy-intensive processes must be considered.

-

Economic Factors: The global economic outlook plays a significant role in the demand for aluminium oxide. Economic growth typically drives higher demand for industrial materials, including aluminium oxide. Conversely, economic downturns can lead to decreased demand and lower prices.

-

Technological Advancements: Innovations in production technologies can lead to cost reductions and increased efficiency in aluminium oxide production. These advancements can help stabilize prices by offsetting rising raw material and energy costs.

-

Environmental Regulations: Stricter environmental regulations can impact aluminium oxide production costs. Compliance with emission standards and waste management requirements can lead to increased operational costs, affecting the overall price trend.

Market Analysis

The aluminium oxide market is segmented based on application, end-use industry, and geography. A thorough market analysis provides insights into the factors driving demand in each segment and their impact on price trends.

-

Application Segmentation:

- Metallurgical Grade: The largest segment, driven by the demand for aluminum production. Fluctuations in the aluminum market directly impact this segment.

- Refractory Grade: Used in high-temperature applications such as furnaces and kilns. The demand here is influenced by the steel and cement industries.

- Abrasive Grade: Utilized in sandpapers, grinding wheels, and cutting tools. The manufacturing sector’s health affects this segment’s demand.

- Ceramic Grade: Used in the production of advanced ceramics. The electronics and automotive industries significantly influence this segment.

-

End-Use Industry:

- Aluminum Industry: The primary consumer of aluminium oxide, particularly in smelting operations.

- Steel Industry: Consumes refractory grade alumina for furnace linings and other high-temperature applications.

- Electronics Industry: Utilizes ceramic grade alumina in various electronic components due to its high thermal conductivity and electrical insulation properties.

- Automotive Industry: Increasingly using alumina in manufacturing lightweight and heat-resistant components to improve fuel efficiency and performance.

-

Geographical Segmentation:

- North America: A significant market due to its robust industrial base and technological advancements in manufacturing processes.

- Europe: Driven by stringent environmental regulations and high demand from the automotive and aerospace industries.

- Asia-Pacific: The largest market, with China and India being major consumers due to rapid industrialization and infrastructure development.

- Latin America and Middle East & Africa: Emerging markets with growing industrial activities and increasing demand for aluminium oxide.

Latest News

Keeping abreast of the latest news in the aluminium oxide market is crucial for understanding the factors influencing price trends. Here are some recent developments:

-

Environmental Regulations in China: China, a major producer of aluminium oxide, has been tightening its environmental regulations. This has led to the closure of several bauxite mines and alumina refineries that failed to meet the new standards, resulting in reduced supply and increased prices.

-

Technological Innovations: Recent advancements in alumina extraction and refining technologies are aimed at reducing energy consumption and production costs. Companies are investing in research and development to enhance process efficiency, which could stabilize or even reduce prices in the long term.

-

Trade Policies: Changes in international trade policies and tariffs can impact the global supply chain of aluminium oxide. For instance, recent trade tensions between major economies have led to uncertainties in supply and pricing.

-

COVID-19 Impact: The pandemic has disrupted supply chains and industrial operations worldwide. The initial phases saw a decline in demand and prices due to reduced industrial activities. However, as economies recover, the demand for aluminium oxide is expected to rise, potentially leading to price increases.

-

Sustainability Initiatives: There is a growing emphasis on sustainable and eco-friendly production practices. Companies are increasingly adopting green technologies and processes, which, while potentially increasing short-term costs, are aimed at long-term sustainability and cost efficiency.

Conclusion

The aluminium oxide market is influenced by a myriad of factors ranging from supply chain dynamics and energy costs to technological advancements and environmental regulations. By analyzing these factors and staying updated with the latest news, stakeholders can make informed decisions regarding aluminium oxide procurement and investment. The market is poised for growth, driven by increasing industrial activities and the ongoing shift towards sustainable production practices. Understanding the price trends and forecast will be crucial for navigating the complexities of this essential industrial material.