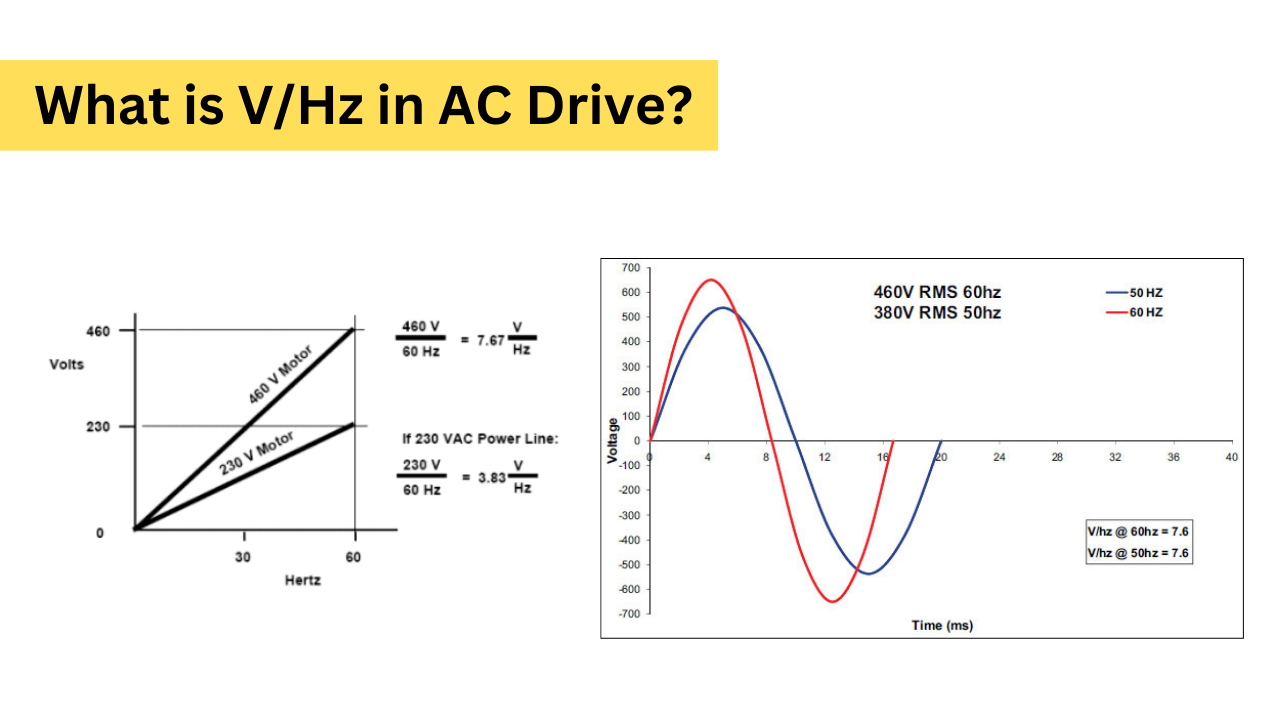

When operating at variable frequencies, AC drives use the V/Hz (Volts per Hertz) control approach to keep the voltage to frequency ratio constant. To regulate the speed and torque of an AC motor in an AC drive, the output voltage and frequency are changed. Here are some crucial ideas regarding V/Hz control:

Motor Voltage-Frequency Relationship:

The V/Hz control technique is founded on the idea that proper motor operation requires a consistent voltage to frequency ratio. The voltage supplied to the motor is adjusted according to the change in frequency of the AC power source to maintain the required V/Hz ratio.

- Proportional Control: In order to maintain a constant V/Hz ratio, the motor voltage and frequency are normally regulated proportionally. The voltage supplied to the motor is modified in accordance with changes in the power supply’s frequency to keep the desired V/Hz ratio.

- Flux Control: The V/Hz ratio is vital in regulating the magnetic flux of the motor, which impacts its capacity to generate torque. To maintain a consistent V/Hz ratio and guarantee that the magnetic flux is maintained at an adequate level for the operating speed, the voltage must be modified as the frequency is changed.

- Constant V/Hz Ratio: The V/Hz ratio is maintained constant within a specific range of motor speeds in the majority of AC motor control applications. Depending on the motor design, the precise V/Hz ratio can vary, but it normally falls between 1:1 and 2:1. The motor performs effectively and dependably at various speeds by maintaining a consistent V/Hz ratio.

Speed-Torque Control:

The AC drive can manage the motor’s speed and torque characteristics by modifying the voltage and frequency that are provided to it in accordance with the V/Hz ratio. The V/Hz control technique enables efficient and effective motor operating over a wide speed range.

- Speed Control: The motor’s rotational speed can be precisely regulated with speed control. The motor speed can be regulated by modifying the output frequency of the AC drive, which is typically how the power supply frequency is adjusted. This is crucial for applications requiring precise speed regulation, like robotics, conveyors, and industrial gear.

- Torque Control: The capacity to control the motor’s output torque is referred to as torque control. An AC motor’s torque output is inversely proportional to its motor current. The torque output can be altered by changing the motor current, often by changing the voltage supplied to the motor. This is essential for applications where precise torque specifications must be satisfied, such as in motor-driven machinery that calls for various amounts of force.

Check :- Allen Bradley AC drives

Motor Flux Control: The V/Hz control technique and motor flux control are closely related concepts. Flux is the term for the magnetic field intensity within the motor, which affects the motor’s capacity to generate torque. The AC drive guarantees that the motor’s flux is appropriate for the operating speed by keeping a consistent V/Hz ratio, enabling dependable motor performance.

- Importance of Flux Control: The electromagnetic field that interacts with the stator windings to produce torque depends on the magnetic flux generated in an AC motor. The output torque, speed, and general performance of the motor can be precisely regulated by managing the flux.

- Flux and Torque Relationship: An AC motor’s torque output is directly inversely proportional to its magnetic flux. It is possible to alter the torque production by adjusting the motor flux. While the torque output decreases when the flux is reduced, it increases when it is increased.

Variable Frequency Operation:

When variable speed operation is necessary, such as in pumps, fans, conveyors, and other industrial gear, AC drives with V/Hz control capability are frequently utilised. To provide the desired speed and torque characteristics, the drive modifies the frequency and voltage supplied to the motor.

- Speed Control: The motor’s rotational speed can be precisely controlled using variable frequency operation. The speed of the motor can be changed across a large range by adjusting the power supply’s frequency. This adaptability is especially useful in applications like pumps, fans, conveyors, and machine tools where variable working speeds are necessary.

- Energy Efficiency: Energy savings are made possible via variable frequency operation, which matches the motor’s speed to the actual load needs. The motor speed can be changed to match the desired output, saving energy as opposed to operating the motor at a set speed and wasting energy. This is particularly useful in situations with fluctuating load requirements since it allows the motor to run at lower speeds when less power is required.

V/Hz Control Methods:

Scalar control and vector control are two approaches used to accomplish V/Hz control in AC drives. In order to obtain more exact speed and torque control, vector control allows for independent adjustment of the motor voltage and frequency as opposed to scalar control, which adjusts the motor voltage and frequency in a set ratio.

To maintain a steady voltage-to-frequency ratio and obtain the desired speed and torque characteristics in AC motor-driven systems, V/Hz control is a fundamental control approach used in AC drives.